A community practices integrated water resources management

On a Saturday morning, K P Singh is surrounded by residents of a neighbouring layout asking questions. Singh, middle-aged and bespectacled, is a resident of Rainbow Drive (RBD), an upscale residential layout along Sarjapur Road in southeast Bengaluru. He is also former President of the layout Plot Owners’ Association (POA). The visitors are here to know about water management at the layout, and Singh is happy to explain. He says this is the seventh such community to visit the layout in the past few months; one community had come from as far as Chikka Tirupathi, 27 kms away.

These layouts, located in Bengaluru’s outskirts, often have borewells that do not yield water. They are also not served by the Bengaluru Water Supply and Sewerage Board (BWSSB). But RBD demonstrates that communities can manage their water very well, by themselves. The layout has a fully decentralised model for water management, where everything from water procurement to wastewater reuse is done by the community itself. Singh describes it as “no water coming into the layout, and none going out.”

As you enter the layout, you can see round concrete slabs inside the storm water drains – these are the layout’s recharge wells. Also, every household here has a rainwater harvesting (RWH) system, which augments water levels in the layout’s two borewells. Residents use just enough water for their needs. Sewage is treated using a green technology that requires very little energy and manpower. Treated water is used for gardening; most houses have vegetable and flower gardens. This means the overall water-related costs of the community is low too.None of this was easy. The layout started its water reforms in 2004, after the POA took over management from the builder. It was then they understood the problematic water situation here. Though the community relied on its own borewells, residents always wasted water. Flooding was common, and water-related expenses were never accounted for. Sometimes this led to conflicts. For example, villagers outside the layout were more affected by floods during rains, since the layout’s compound wall kept the water out. The flooding was because the layout was built over a natural drainage path. During one rain, villagers’ houses got submerged and they demolished the layout’s wall. This in turn caused the layout’s front gate to be flooded up to five feet.

Such incidents convinced the community that water management was necessary. The POA’s Management Committee (MC) initiated one reform after another over a decade, learning, debating and experimenting. Multiple reforms reinforced each other, finally leading the layout to have an integrated water management system. Getting the community’s approval was important for this. There was no legal basis or incentives from the government to enforce these reforms; no was there any blueprint or existing model. To implement every reform, residents had to be engaged with, and convinced. The POA, in turn, had to deliver water services perfectly so that residents would accept new reforms.

The reforms began with the POA realising that high water demand was the layout’s central problem. Residents were used to getting free water from community borewells, and never gave it a thought.

Reigning in water demand

Potable borewell water was commonly used for hose-washing cars and building new houses, and overhead tanks overflowed often. “Residents never had to buy tanker water then, and they never thought of borewells as a finite source. When I talked about water management, people just nodded and forgot about it,” says former MC member Jayawanth, who was among the first to initiate the reforms.

But some residents were already concerned about a few plot owners digging private borewells. Water from these borewells were mostly used for house construction, and residents were concerned that these would reduce the community borewells’ yields. POA banned the drilling of private borewells entirely, and allowed only the use of community borewells. Authority of an expert, and the strength of numbers were pivotal here. A hydrogeologist invited to the layout, pointed out to residents that any more than 10-15 borewells would deplete groundwater levels here. Second, most plot owners had already moved into the layout and did not require private borewells for house construction. Concerned about groundwater depletion, they pushed others to accept the ban, says Jayawanth.

In 2006, POA installed consumption meters for each household, and started billing them based on meter reading. Tariff was fixed at Rs 6 per KL. With this, the consumption of each household was known, and they had to pay only according to their usage. Residents were expected to reduce their usage, but this did not happen. Because of the low tariff, residents’ monthly bills were only Rs 200-300, an amount they were easily willing to pay. But consumption metering gave the POA data that would spur further reforms.

POA realised that high amounts of community borewell water was used for construction. So POA decided that only tanker water could be used for construction henceforth. Metering data also showed that some of the residents were extravagant – a third of residents were using half the layout’s water. This was also when POA found that four backup borewells were in fact dry. So the only water sources were the two borewells which were currently yielding. Hence reducing demand was critical.

Jayawanth’s calculations also showed that the actual production cost of water was far more than what residents were paying. Production cost included the cost of borewell and water tank maintenance, fixing leaks, operating sewage treatment plant (STP) etc. STP operations alone made up half the production cost. But none of these were ever accounted as water costs, and were paid directly from the maintenance fund and thus split equally among all. STP expense would in fact vary across households depending on their sewage generation, i.e, based on their water use. Factoring in all expenses, the cost of water was Rs 16-17 per KL. The current tariff of Rs 6 per KL covered only the electricity cost of pumping water. Some defaulted on this bill too. All of this led the POA to draw from its Fixed Deposits in 2007-08.

Having understood the real cost of water, POA set a scientific tariff. The tariff also had to incentivise RWH, which POA initiated at the time. Since the new tariff would raise bills sharply, POA first shared its research with the community, and held discussions. Developing a larger water consciousness among the community was important.

The new tariff in 2008 aimed to:

- Recover the production cost of water

- Incentivise frugal use, penalise wastage: Higher tariffs were set for higher slabs of water use, i.e., volumetric increasing block tariff was implemented. For a household whose monthly usage was up to 10 KL, tariff was Rs 10 per KL. But for those using 11-20 KL, Rs 15 was charged per KL, and so on. For the highest slab – those using above 60 KL – tariff was Rs 60 per KL. That is, for each KL of water, the households using the most water had to pay six times that paid by households using the least water.

- Incentivise RWH: For households that implemented RWH got discount of Rs 100 on their bill.

- Avoid delay in payments: Residents had to pay penalty of Rs 10 for every day of delay. From once in two months, the billing cycle was changed to once a month.

“Residents paying Rs 200-300 were now paying Rs 3000-5000 per month. Some resisted, but some changed their behaviour. Many residents said that they would not have found and fixed the leaks in their houses if it was not for the tariff hike,” says Jayawanth.

In 2008-09, water demand was still 246 lpcd (litres per capita per day), compared to the recommended use of 135 lpcd in urban areas. By 2010, water costs increased further, and borewells started drying. The community was familiar with the scientific tariff setting process by then. From 2010 to 2015, tariff was raised multiple times. Since 2011-12, water was rationed. By 2015, water demand reduced to 150 lpcd.

Presently, the highest slab of usage is above 25 KL, compared to 60 KL earlier. For those using above 25 KL, tariff is Rs 120 per KL, higher than the market rate of Rs 100. “Hardly any household uses over 25 KL per month now. Those using so much can buy tanker water. Some new houses that integrated RWH in their design use rainwater alone,” says Singh. Currently water is supplied once in three days only to each household – 2000 litres is supplied at a time, so that the household uses 500-600 litres per day.

Even while reducing demand, community borewells had to be kept alive. RWH was the answer.

Enhancing groundwater

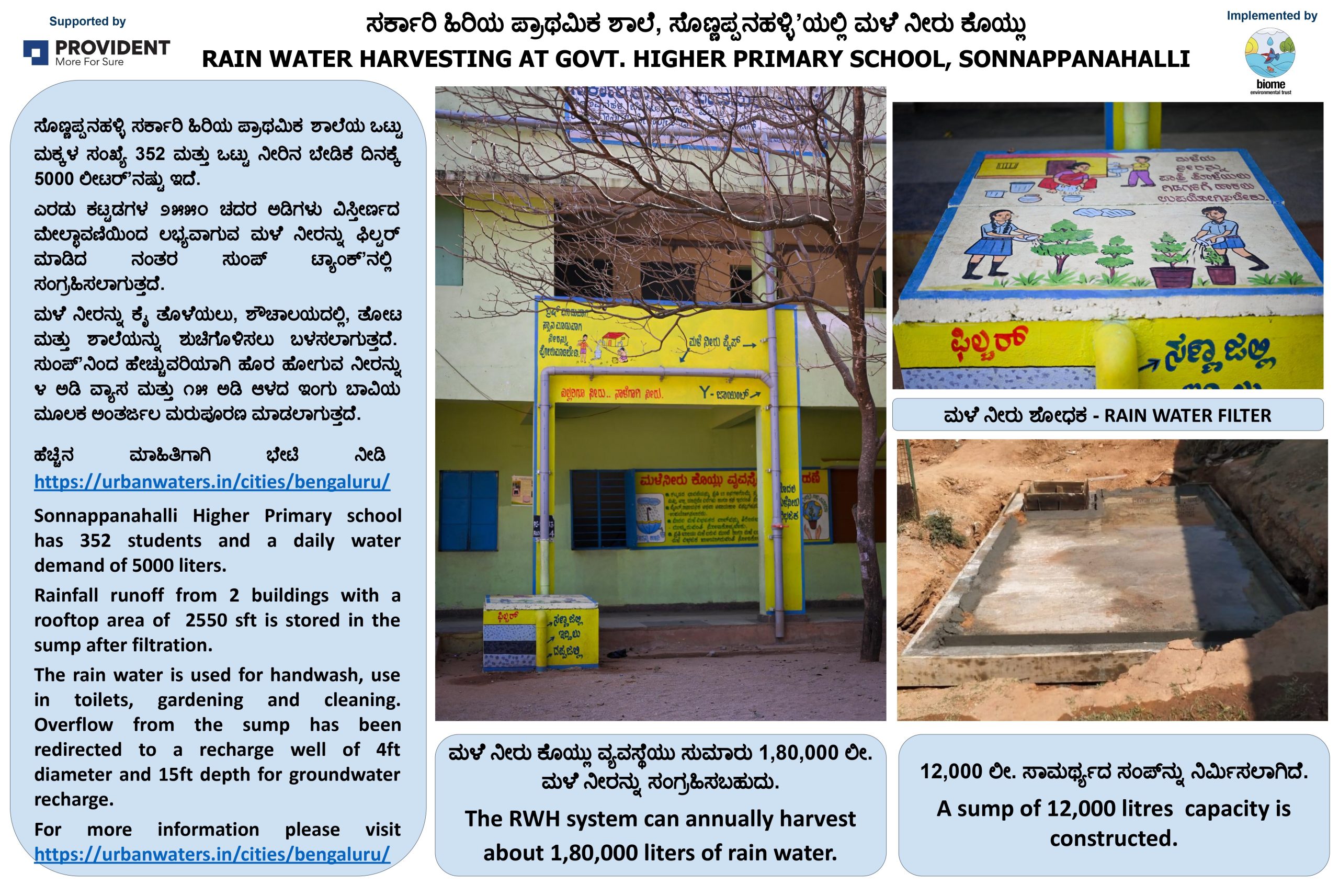

Since 2007, MC members installed RWH in their households and cajoled others to do the same. Experts were invited to talk to residents, and POA members went door-to-door enrolling people for RWH. As a demonstration, 20 recharge wells were dug before the 2008 monsoon. As recharge wells captured rainwater, preventing flooding, residents got interested. POA gave the households the option of either setting up a RWH storage or recharge system in their own plots, or to sponsor a recharge well in common areas. Recharge wells were mostly dug in the layout’s open SWD network that captured most of the rainwater.

In 2009, BWSSB made RWH compulsory. In 2011, POA made it compulsory as per the layout’s bye-laws; those who did not implement RWH did not get water supply. Now all houses here do RWH. There are recharge wells within SWDs, every 50 metres, of 3 ft diameter and 20 ft depth. There are also 5-6 big recharge wells in the common plots, of 5 ft diameter and 30-40 ft depth. Overall, there are some 350 recharge wells here.

Due to recharge wells, water levels have increased in the two borewells that were starting to dry up. These borewells, over 16 years old, have depth of 170-180 feet only. Though the community tried digging 6-7 borewells over the past decade, only one of them yield, that too only half the year. This borewell is around 780 feet deep. “Recharge wells send water to the layout’s shallow aquifer (permeable rock layers carrying water at shallow levels). Since the two old borewells are shallow, they benefit from the recharge we do. The new borewell is too deep to benefit from recharge wells,” says Singh.

A weather station installed in the layout has shown that the amount of rain falling in the layout is twice that of the water used by residents. “So even if half the water we put into the ground comes into the borewells, we can survive,” says Singh. Currently, the community recharges more water than it draws from its borewells, thus becoming ‘water positive’.

As residents saw the benefits of recharge wells, they understood the concept of sustainability better, and were more open to other reforms like tariff hikes.

Next, the POA dealt with the dysfunctional STP.

Harnessing wastewater

In Bengaluru, apartments/layouts are mandated to have their own STPs, yet most of these are as good as non-existent. Due to poor design and operations, their treated water is often no better than raw sewage, and it is let out into public spaces. RBD’s case was similar. It had two STPs that operated on the conventional ASP (Activated Sludge Process) technology. Over 18 years old, these STPs would stop functioning properly every few months. “The quality of treated water would be poor, and we would just let it out into the stormwater drains outside the layout,” says Singh.

Besides, operating the STPs was very expensive. In 2012, monthly operating expense was Rs 80,000-1,00,000. The plants ran on 15 motors that needed frequent repairs, which was expensive and could be done only at the faraway KR Market. “It was like running a full-scale industrial plant”, recalls Singh. STP operation had been outsourced to an agency at the expense of Rs 32,000 per month. The plant required much energy and full-time operators.Rather than increasing the financial burden on residents by investing in the current STPs, the POA started searching for cheaper, green technologies. They came across natural treatment methods like Soil Biotechnology (SBT) and Phytorid technology. A sub-committee studied these options for 3-4 years, travelled to meet experts and observe existing models. Finally they adopted Phytorid technology developed by the central government institute NEERI (National Environmental Engineering Research Institute).

Here, the economic argument made sense to residents. The new STP would need capital investment of Rs 85 lakh, including the cost of pipes to distribute treated water for reuse to households. But its operating cost would be only Rs 10,000-12,000 per month, which was Rs 70,000-80,000 lesser than that of the current STP. “So our initial investment could be recovered in 4-5 years. We decided to answer residents’ questions with patience, and contacted NEERI when we had any doubts,” says Singh. Plot owners paid Rs 20,000 each, which came to a total of Rs 76 lakhs. “Getting money from owners who lived abroad was difficult, but we convinced them,” he says.

Since the community had already reduced its water demand to 150 lpcd, the STP capacity required was correspondingly low. This meant much lower investment too. Reuse of treated water, in turn, reduces the community’s water demand too.

Set up in October 2014, the STP releases one lakh litres of treated water, which is distributed to residents for gardening. Some like Singh use it to wash cars too. “This water costs Rs 10,000 in the market. It has reduced the use of borewell water for gardening,” says Singh. The treated water meets discharge norms of the Karnataka State Pollution Control Board (KSPCB). POA is on discussions with the Board to allow treated water to be sent to recharge wells directly. A fully civil construction, the STP needs only two motors, no operators and hardly any maintenance. Singh says phytorid plants are particularly useful for small apartments since their per capita expense for a conventional STP would be very high.

RBD’s story shows how individuals can unite to take actions that may seem contrary to their self-interest at the time, but would benefit everyone in the long term. The community has been able to self-regulate over a span of 10 years despite changes in leadership. Their multiple interventions – RWH, reducing demand, and having an efficient STP – have reinforced each other. RBD is an example of how urban citizens can be autonomous in water management, rather than rely on an external authority.

Phytorid Plant

| Capacity | 250 KL per day |

| Components |

|

| Implementation | Sewage from all tanks go into the PST, which contains both aerobic and anaerobic bacteria that digest sewage. Sewage flows in a cascade here. It is then pumped up into the phytorid bed. At the phytorid bed, the plants absorb nutrients and pathogens in the water. Treated water from phytorid bed is pumped up to two overhead tanks. From here, water flows by gravity through distribution pipes, to each plot. |

Further Reading:

Rainwater Harvesting in Rainbow Drive